Product Description

The device can be used in food, pharmaceutical, chemical,textile and garment, toy industry and so on, which is authorized by HACCP(food industry), GMP(pharmaceutical industry), and it can be applied for cookies, sauces, dumpling, hum, soup, candy, meat, frozen food, salted food, fast food, bakery etc, and other industries that have special requirements on detection sensitivity, anti-interference, waterproof. Besides, it can detect broken needles, metals mixed with products.

- Dual-loop circuit design, it can detect ferrous and non-ferrous and other metal objects, the sensitivity can be adjusted separately, with memory function can be stored 10 kinds of test material.

- Detector with audible and visual alarm, and automatically exclude, stop, rewind functions, user-friendly menu, easy to operate touch screen. Machine made of stainless steel,anti-corrosion, no rust, easy to clean up.

- Conveyor and pallet assembly used in the U.S. “F.D.A.” standards of white non-toxic materials.

- Detection accuracy over the corresponding provisions of HACCP system Detect indicators.

- Can use with production line.

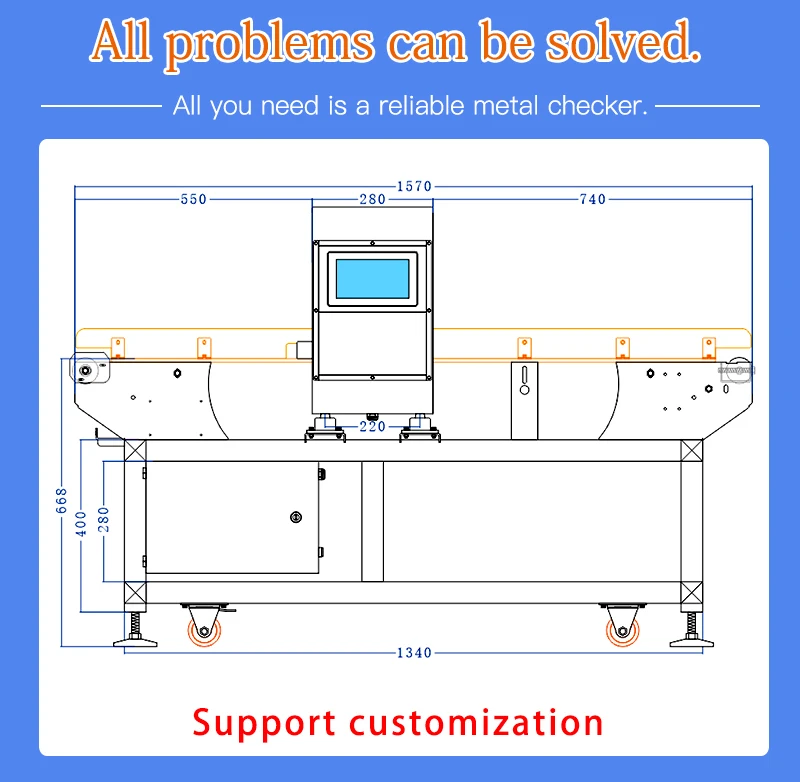

- Detected Height(mm)80100150200250300350Belt Width(mm)250250400400400400400Belt length1500Detector sensitivity(mm)Fe 0.8Fe 1.0Fe 1.2Fe 1.5Fe 2.0Fe 2.5Fe 3.0SUS 1.0SUS 2.0SUS 2.5SUS 2.5SUS 3.0SUS 3.5SUS 4.0N-Fe 1.0N-Fe 1.5N-Fe 2.0N-Fe 2.0N-Fe 2.5N-Fe 3.0N-Fe 3.5Speed of belt25M/min (Fixed speed) ;

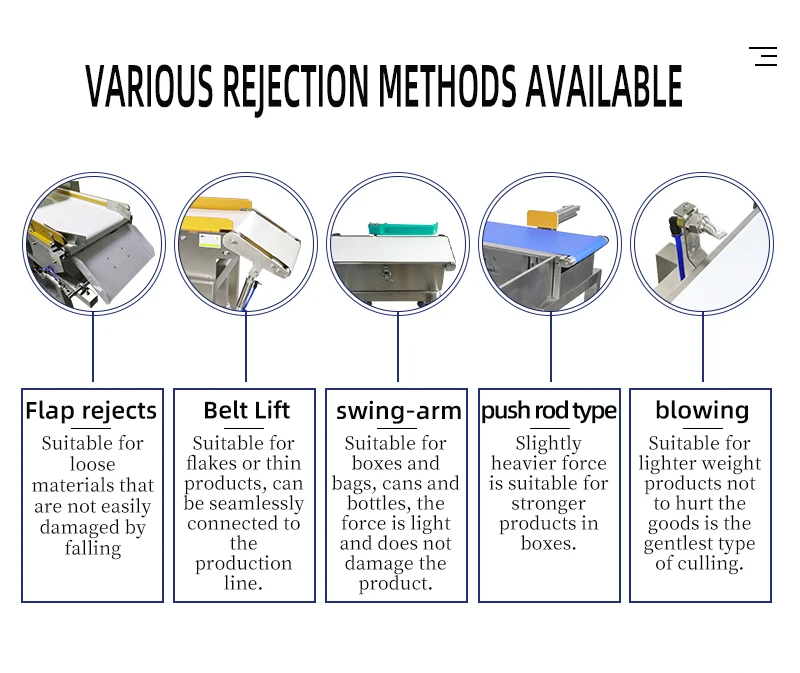

If you need adjust 5-40 M/min , please inform us before orderLoad ability20KGCount100Warning methodSound and light alarm ; The belt can be stopped, continue run or belt return ( the option you can selected in PLC controller)Reject Wayswhen has auto-reject system ,belt continue and rejecting the goodsApplicationNon-package ,plastic package ,paper bag or box (non-metallic) productWork EnvironmentTemperature -10℃-40℃ ,relative humility 30-90% Description:

Metal detector for food industry

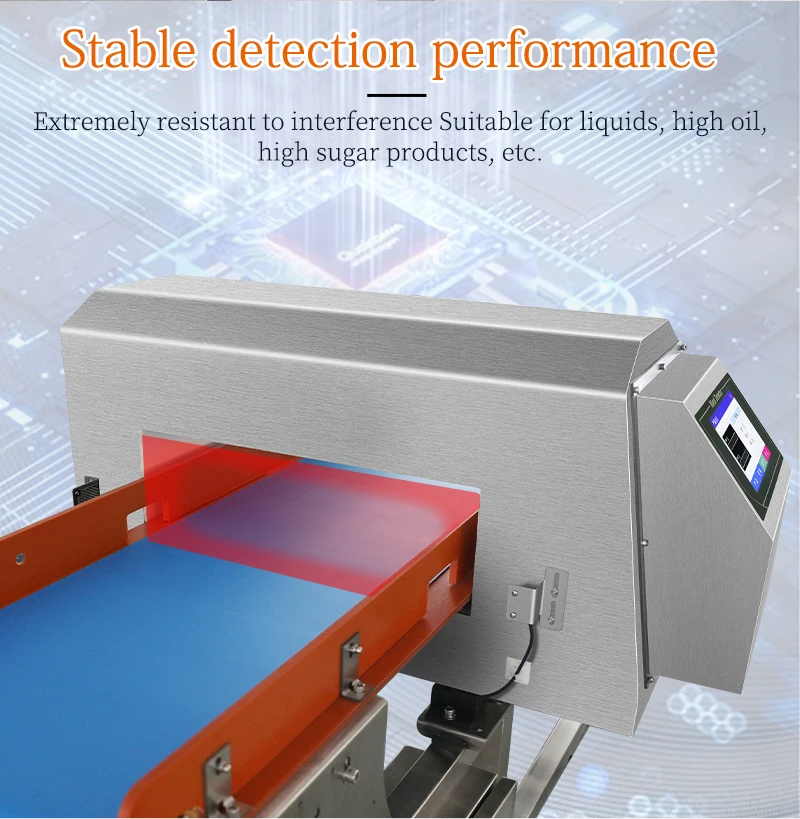

is new arrival food metal detector . It has touch screen , 10 level adjustable sensitivity and

memory 24 kinds of products etc .But also it has more higher reliability and stability on check products with water and salt.

1. Adopt the theory of balance, more reliable;

2. Phase-adapted technology can adapt products in order to effectively eliminate product effect.

3. Combination of DSP and Microprocessor is applied to process testing data of detection signal, which can enhance detection

efficiency.

4. To stop mistaking in transmission & reception in advance, the detector handles many operations. Easy to adjust the detecting

parameters.

5. Large LCD display with Chinese & English language and so on; Consumer can choose according to their needs.

6. Have self- learning study function, can automatically digitally learn and store product’s features.Easy to operate without

manual participation to adjust technical parameters.

7. It can store more than 24 kinds of testing data of products.

8. Automatic rejection system can be customized according to consumer’s requirements, which can improve production efficiency and

save labor costs.

9. Suitable for wet, dry ,dust ,dew environment , made of stainless steal ,has HACCP attestation , waterproof IP65

1.Belt-down reject Suitable for loose and thin products, seamless integrated to production line 2.Stable and high sensitivity & precision Mature phase adjustment technology, avoiding shortcomings like no phase of LC analog circuit, low stability, without products suppression function and machine aging caused by time and temperature 3.Auto-setting function Fast learn product character automatically and finish Auto-setting process. 4.New Function: -Phase tracking function with can maintain the stable high-sensitivity detection ability -Product tracking function, which can do adjustment and compensation according to the changes of the product effect automatically – Auto-balanced calibration function, which can ensure the service lifetime of the the machine 5.User friendly function Automatic rewind function, dispense with handling large product 100 products can be restored in database USB and Ethernet interfaces are available LCD, Chinese-English touch screen, easy operation International languages customized 6.Easy to be cleaned